ORGANIC OPTION

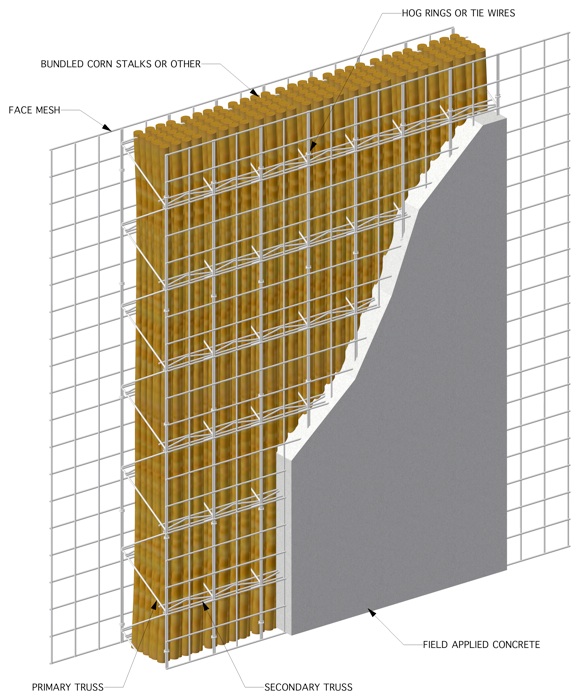

The inflatable tubes were shown, on the Welcome page, because they offer the greatest ease of use and fastest assembly. However, since displacing concrete and not structural integrity is the primary purpose, of the tubes, as is the foam core in other space frame panel systems, almost anything that is not water soluble can be used. Alternate filler materials such as bundled corn or sugarcane stalks, reeds, grasses, other agricultural byproducts, or even recycled material could be used. The plastic tubes could be filled with recycled polystyrene (or other) foam, shredded tires, PET bottles, saw dust, or just about anything Depending on the filler used, the panel cost would decrease and the insulation value could be improved. Also, air pumps would not be required and, in disaster areas, needed additional employment would be provided.

In order to facilitate the use of stalks, reeds, or grasses they should be bundled in simple rectangular forms made to the dimensions of spaces between the primary trusses. This would simplify the fabrication of the fillers and their use in the assembly of the panels. Cores of recycled materials would be made in the same mold, with the same process but with sheet plastic laid in after the strings. The material, whether shredded tires or crushed plastic bottles, would be pressed in, the plastic wrapped around, and the strings tied to secure the bundle, with the ends of the tube, so created, tied with more string.

We are also investigating the possibility of substituting woven bamboo mats for the welded wire face mesh, as shown in the schematic drawings.