THERMAL INSULATION

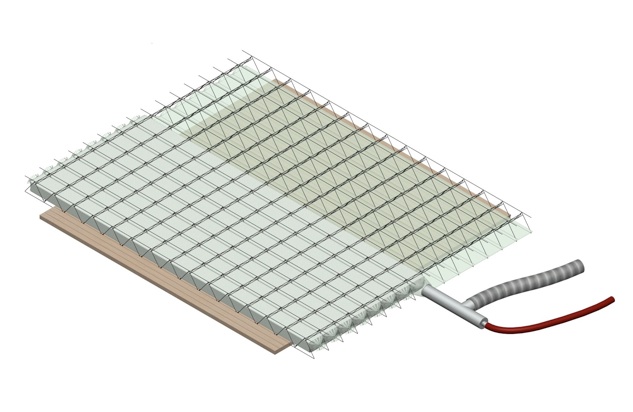

Thermal insulation is an energy efficiency design parameter for buildings in much of the world where heating and/or air conditioning are required, for comfort, or as an industrial process demand. StructaPanel can be readily insulated, at a negligible increase in cost, by substituting loosely woven porous polypropylene tubes, for the extruded inflatable tubes (as illustrated elsewhere), which are filled with blown-in expanded polystyrene beads. Loosely woven polypropylene fabric is inexpensive and is available from many sources worldwide and can be sewn, on site, into tubes of whatever dimensions are required.

Assembly of the panels is the same as shown for other fillers, but for insulation the expanded beads are fed from a hopper or silo and by means of a venturi eductor are blown into woven tubes (as shown below). The porosity of the tubes allows the air to escape until the tubes are full of the EPS beads, whereupon the tube ends are closed with a hog rings or bag ties.

With this tube and filling the typical StructaPanel assembly will provide an U-Value of 0.28 (W/m²K)

Many climates and structural designs require thermal insulation in on-grade slabs, exterior walls, and roofs. A variation of StructaPanel displacement cores can provide insulation without compromising the system’s benefits.

One of the principal attributes of StructaPanel is the elimination of the need to transport large volumes of EPS from a manufacturing facility to the point of use. We are therefore developing a proprietary energy efficient method and the equipment for on-site expansion of granular polystyrene resin into low density EPS beads, without the customary use of steam. This apparatus will be of small size, inexpensive, and easily used.

For projects exceeding 100 units, conventional low volume EPS steam pre-expanders, would be economically feasible.

StructaPanel can deliver low U-Value structures with only minimal increase in transport volume and weight, over the uninsulated basic version and still far surpasses other available EPS core modular panel systems.

TYPICAL ASSEMBLY AND FILLING

Venturi Eductor

High Volume Low Pressure Air

EPS Bead Silo or Generator