ASSEMBLY

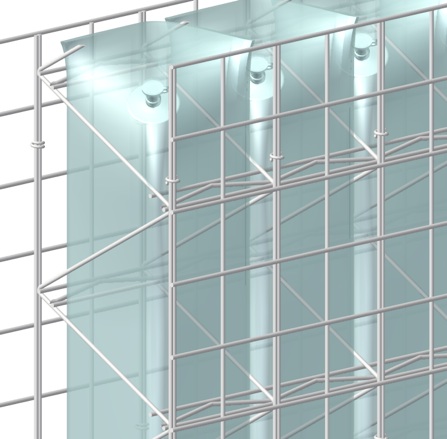

The video, below, illustrates the assembly of a 3 m. x 3 m. panel with 15 cm. spaces between the primary trusses. The assembly jig is made of plywood strips fastened to a plywood base so that the 3 mm. slots between them are 5 cm. on center. The jig can be easily made larger to accommodate bigger panels

The primary and secondary trusses can be readily fabricated up to 12 m. in length, to be cut, on site, for assembly of structural elements in sizes as required and/or to maximize convenience of handling and installation. The tubes are supplied in 500 m. rolls to be cut, with the ends and inflation valves thermally welded, on site, as needed. The primary trusses can be placed as close together as 5 cm. or as far apart as structural requirements would warrant, with the proper sized intervening inflatable tubes. This allows for a wide range of possible variations in strength and insures that no more material is used than what is necessary. Where structural requirements dictate, after concrete is applied to one side of the panels, tubes can be selectively removed to allow for the insertion of rebars and placement solid concrete, for the formation of beams and columns or to increase shear transfer reinforcement between the two wythes of the panel.

The inflatable tubes have been shown because they offer the greatest ease of use. However, since displacing concrete is their primary purpose almost anything that is not water soluble can be used. Alternate filler materials such as bundled corn stalks, other agricultural byproducts, or even recycled material could be used. Depending on the filler used, the panel cost could decrease and the insulation value could be improved. See Organic Option and Insulation pages.

The secondary trusses have a two-fold purpose; to provide lateral stiffness, to the panel, and space between the inflated tubes and the face mesh needed to insure full encapsulation of the mesh, by the applied concrete.

Of course the wire gauges of the constituent parts can be altered according to engineering demands and can be decreased by the use of fiber reinforced concrete. In an effort to minimize the carbon footprint of the product the use of bamboo or other plant fiber as concrete reinforcement would be desirable.